Smidnya Technologies: Pioneering Innovation in Industrial Automation

At Smidnya Technologies, we are committed to transforming the landscape of industrial automation with cutting-edge solutions tailored to meet the evolving needs of modern industries. Established with a vision to bridge the gap between operational challenges and smart technology, Smidnya has quickly grown to become a trusted partner for businesses across sectors like manufacturing, pharmaceuticals, FMCG, packaging, and more.

Who We Are

Smidnya Technologies is a technology-driven company focused on delivering advanced automation and control systems that improve operational efficiency, ensure product quality, and reduce downtime. Our team consists of experienced engineers, designers, and developers who bring innovative ideas to life through precision engineering and customized solutions.

We believe in empowering industries through smart systems that integrate seamlessly into existing workflows, helping businesses stay competitive in an increasingly digital world.

What We Provide

1.Cobots

Automation That Works With People — Not Just Around Them

Why Choose Cobots?

- Simple to Set Up and Use

You don’t need to be a robotics expert. Cobots are easy to program through user-friendly software and even hand-guided teaching. Your team can get up and running with minimal training.

- Flexible for Any Task

Whether you need help with packaging, assembly, machine loading, quality inspection, or palletizing, cobots can handle a wide range of repetitive or precision tasks — and easily switch between them when needed.

- Quick to Deploy, Easy to Move

Lightweight and compact, cobots can be installed in just a few hours and moved between workstations with little downtime. Perfect for high-mix, low-volume environments.

- Affordable Automation

Cobots offer a fast return on investment. With lower installation and maintenance costs, they make automation accessible — even for small and mid-sized businesses

Our Cobot Solutions

We don’t just deliver robots — we deliver complete solutions. From grippers and vision systems to custom end-of-arm tools and integration with your existing equipment, we tailor each cobot setup to your specific needs. Our team ensures everything works seamlessly, so you can focus on what matters most: productivity, quality, and growth.

2. PLC-Based Control Panels

Why Choose Our PLC Panels?

1. Precision Control in Real-Time

Our PLC panels enable precise monitoring and control of every critical parameter in your production line — from temperature, pressure, and flow rates to motion control and machine cycles. This real-time responsiveness enhances process efficiency and product quality.

2. Scalable & Modular Architecture

Whether you’re automating a single machine or an entire plant, our PLC panels are built with scalability in mind. We offer modular solutions that grow with your operational needs — allowing easy integration of additional sensors, actuators, and logic layers.

3. Seamless Connectivity

Equipped with Ethernet, Modbus, Profibus, and other industrial communication protocols, our panels integrate smoothly with SCADA systems, HMIs, and enterprise-level software for centralized control and analytics.

4. Robust & Reliable Build

Engineered for tough industrial conditions, our panels use high-quality enclosures, branded PLC components (like Siemens, Allen-Bradley, Mitsubishi), and structured wiring layouts. This ensures durability, safety, and easy troubleshooting.

5. Customization to Industry Needs

From pharmaceuticals and packaging to automotive and FMCG, our control panels are tailored to meet the specific process requirements and compliance standards of each industry.

3. Track and Trace system

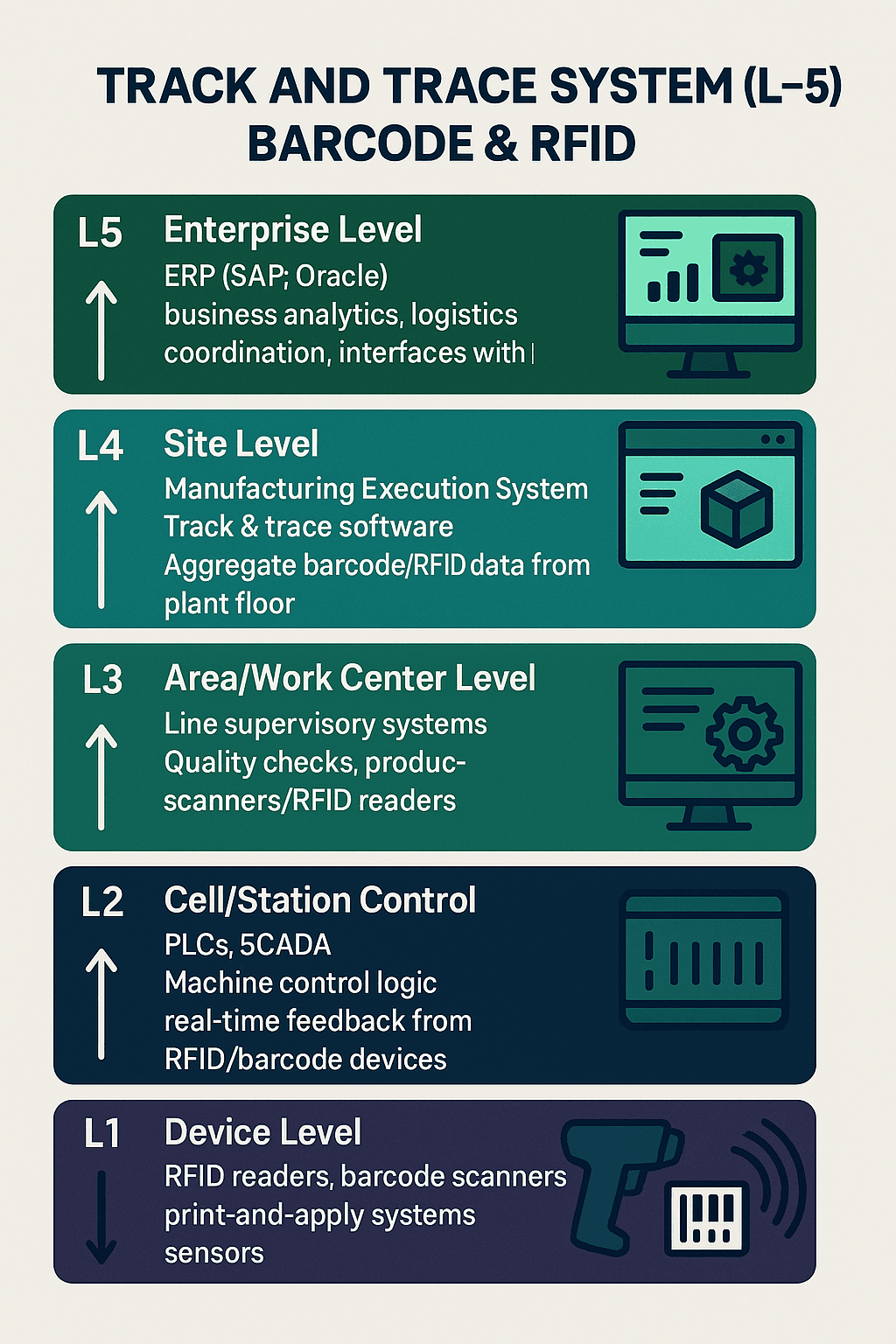

L1–L5 Barcode & RFID Track and Trace Systems

🔹 L1 – Device Level: Capture at the Source

At the base of the stack, traceability begins. Devices interact directly with physical items such as products, pallets, or components.

Technology in Use:

Print-and-apply labelers, handheld barcode scanners, fixed RFID readersPurpose:

Real-time, automatic data captureExample:

A barcode is printed and applied during packaging, scanned immediately, and logged into the system.

🔹 L2 – Cell/Station Control: Intelligent Line Management

This level controls how products move and behave on the line, based on data from L1.

Technology in Use:

PLCs, SCADA systems, industrial HMIsPurpose:

Automate processes like sorting, rejecting, or redirecting productsExample:

A product failing RFID validation is automatically diverted for inspection.

🔹 L3 – Area/Work Center Level: Operational Coordination

This layer ensures localized control and quality enforcement, using data from the production line.

Technology in Use:

Line management systems, quality control platformsPurpose:

Manage batch integrity, enforce traceability standards, optimize workflowExample:

A line halts automatically if a batch is missing RFID tags, preventing untraceable output.

🔹 L4 – Site Level: MES & Plant-Wide Monitoring

The Manufacturing Execution System (MES) integrates all plant-level data into actionable insights.

Technology in Use:

MES platforms, traceability middleware, central plant databasesPurpose:

Enable real-time visibility and decision-making across the siteExample:

MES detects recurring labeling errors from a specific machine and schedules proactive maintenance.

🔹 L5 – Enterprise Level: Strategic Integration

At the top, ERP systems synchronize production data with business operations and supply chains.

Technology in Use:

SAP, Oracle ERP, cloud-based analyticsPurpose:

Drive enterprise-level decisions, automate compliance, and align with demandExample:

A returned item is traced to the supplier and batch within seconds — enabling swift investigation and action.

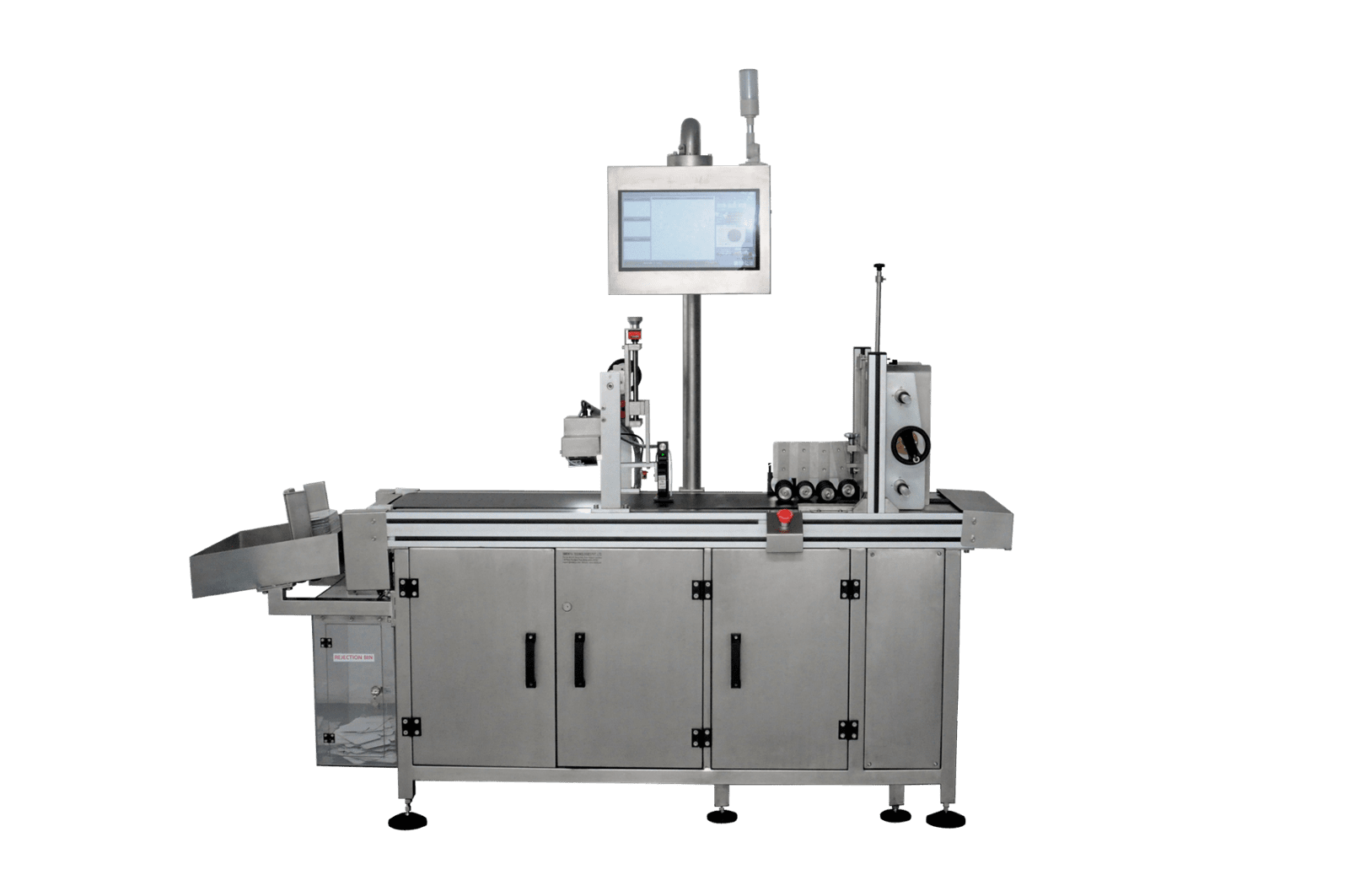

4.Stacker Feeder System

Why Choose Our Stacker Feeders?

1. Continuous, Jam-Free Feeding

Our stacker feeders are built for non-stop operations, handling items precisely with minimal error. The anti-jam mechanisms ensure consistent uptime even in high-throughput environments.

2. Fully Customizable Design

From size adjustments and stack capacities to drive types and sensor integration, every machine can be tailored to suit your specific product, material type, and feeding direction (horizontal/vertical).

3. High-Speed Performance

Engineered with powerful motors and smart controls, our machines can handle hundreds of items per minute — ideal for industries where speed is critical.

4. Smart Integration

Our feeders integrate seamlessly with PLC panels, HMI systems, and vision inspection units, enabling synchronized control, error detection, and feedback-based automation.

5. Reduced Manual Labor & Human Error

By automating the feeding process, you reduce the dependency on manual stacking, improve safety, and eliminate inconsistencies caused by fatigue or misalignment.

5. Vision Inspection Systems

Why Choose Smidnya’s Vision Systems?

1. High-Speed, High-Accuracy Inspection

Our systems are capable of detecting minute defects, inconsistencies, or misalignments at extremely high speeds — ideal for mass production environments where manual inspection is impractical.

2. Multiple Inspection Types in One System

A single unit can perform various types of inspections, including:

- Surface defect detection (e.g., scratches, stains, dents)

Dimensional checks (e.g., length, width, gap, tilt)

Pattern matching (e.g., label/logo verification)

3. Seamless Integration

Our inspection systems are designed for smooth integration with existing infrastructure such as conveyors, robotic arms, PLCs, and reject mechanisms — ensuring cost-effective deployment.

4. AI & Deep Learning Support

For complex or variable defects, our systems can incorporate HALCON or TensorFlow-based AI modules that learn from datasets and continuously improve inspection accuracy.

5. Custom-Built for Your Application

We tailor each system to your unique inspection requirements, selecting the right resolution, lighting, lens, and logic to suit your specific component or packaging line.